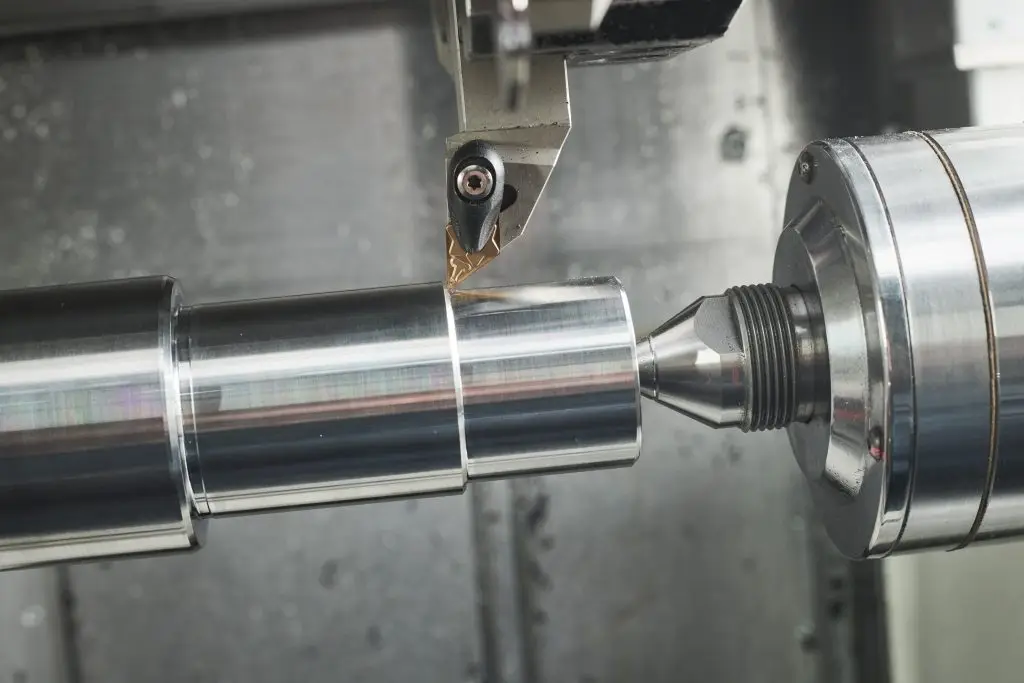

CNC Turning

ASSET Solutions provides precision CNC turning services. We have several turning centers ideal for high volume, high production environments. We utilize automation where we can to improve our manufacturing capabilities and efficiency.

- Precision to a couple tenths of an inch (0.0002")

- Work envelope of 0.060" to 15" in diameter

- Aluminum, stainless steel, titanium and plastics

- Prototype to production parts manufacturing

- Manufacturing Execution System (MES) for job process repeatability

- Quality Management System (QMS) for in process inspection documentation

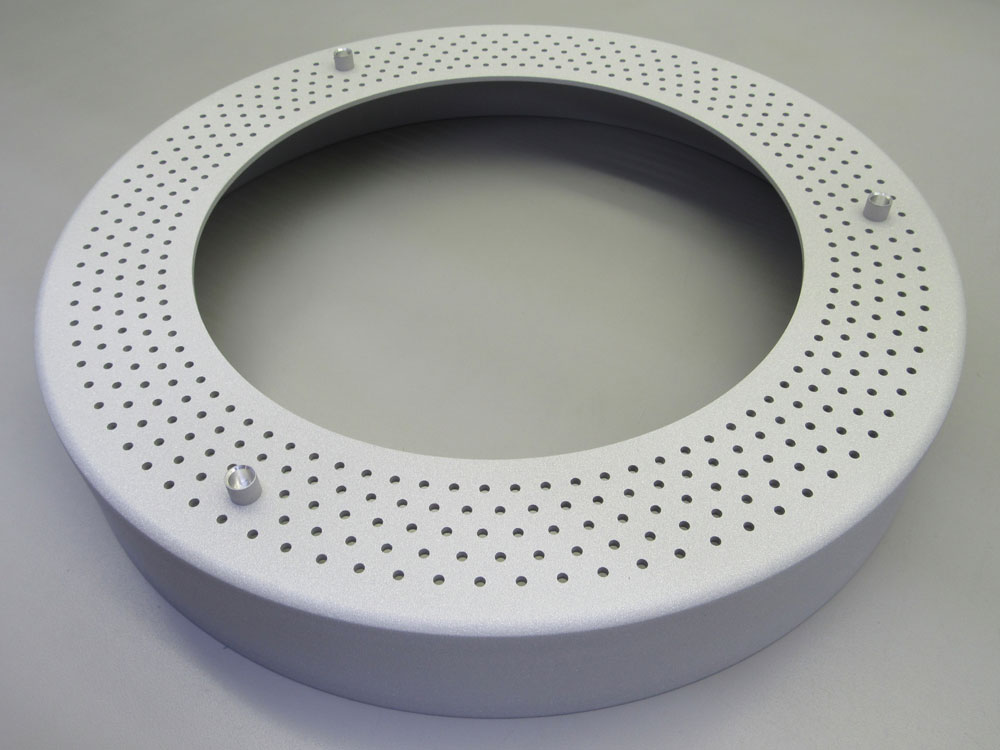

CNC Milling

ASSET Solutions provides precision CNC milling services. We have several vertical milling centers ideal for high volume, high production environments. We utilize automation where we can to improve our manufacturing capabilities and efficiency.

- Precision to a couple tenths of an inch (0.0002")

- Maximum work envelope of 50" (X) by 20" (Y) by 25" (Z)

- 4th and 5th axis capabilities

- Aluminum, stainless steel, titanium and plastics

- Prototype to production parts manufacturing

- Manufacturing Execution System (MES) for job process repeatability

- Quality Management System (QMS) for in process inspection documentation

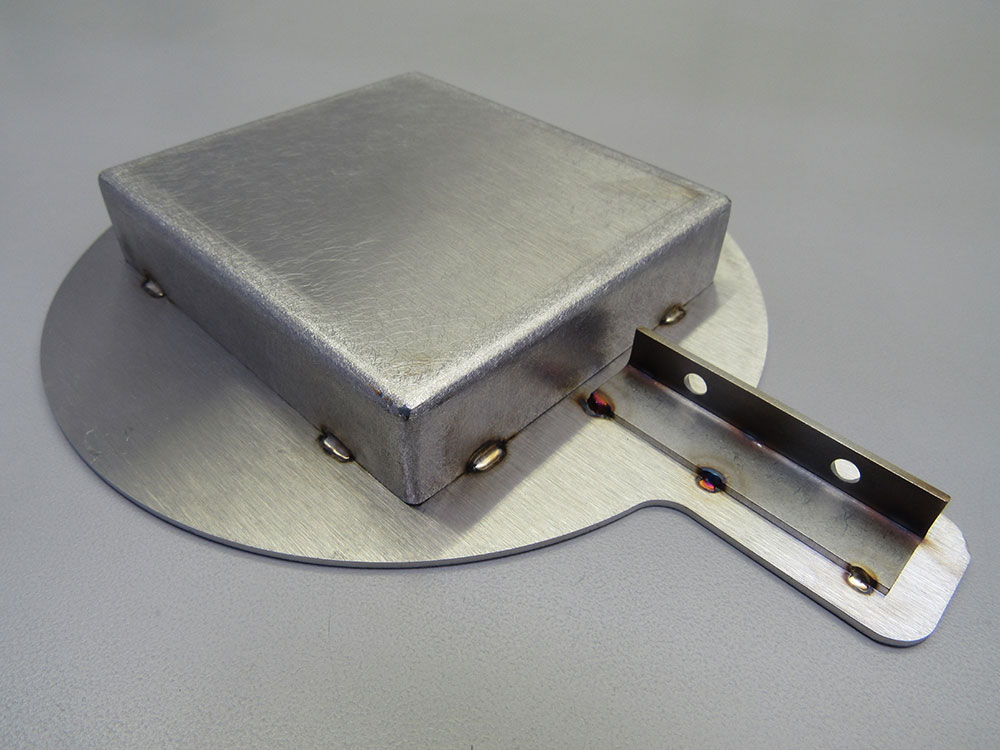

Sheet Metal Fabrication

ASSET Solutions provides precision sheet metal fabrication services. All of our sheet metal products are manufactured to the highest industry standards. We’ve been manufacturing sheet metal components since our inception in 2003.

- Sheet metal bending

- Sheet metal rolling

- Metal spun parts

- 3 and 5 axis laser cutting

- MIG and TIG welding

- Prototype to production part manufacturing

Quality Assurance

All of our products go through a rigid quality assurance process prior to heading out to our customers. Referencing one of our core values – “we believe quality and repeatability are paramount”. With this being stated, it is very important to us that we live up to our core values and they’re not just empty words being used to obtain your business. Multiple in-process inspection points are established at the beginning of each jobs set up, during a jobs manufacturing processes and again prior to shipment to our customer. Over the years, we’ve learned from our experiences and invested countless time and capital to help confirm that our quality assurance is optimum.

Our measuring instruments are calibrated at regular intervals using measurement standards registered with the National Institute of Standards (NIST). All calibration results are recorded in our Quality Management System (QMS) software, which provides an easily accessible register for documenting a measuring instruments accuracy. Once a measuring instrument is calibrated, we’re able to fine tune our measurements by adding or subtracting the instruments standard deviation within its predetermined tolerances.